Indutherm TF 1200, TF 2000, & TF 4000 Tilting Furnace

|

|

|

Highly cost-effective, safe, and powerful.

- New induction generators with high efficiency.

- High maximum output for fast heating up and thorough mixing and homogenization of the molten metal – but significantly reduced effective power consumption.

- Save and easy filling and pouring-off.

- LCD display and program control with 20 temperature programs.

- Three different crucible capacities: 1,200 ccm, 2,000 ccm, 4,000 ccm.

Tilting Furnaces for melting and casting large quantities into ingots or shell molds

The new TF 1200, TF 2000, and TF 4000 models, which, like their predecessors, are used in the jewellery industry and in precious metal foundries, are completely new developments. They are equipped with new high performance induction generators that reach the melting point significantly faster and ensure thorough mixing and homogenisation of the molten metals. Depending on the model, the capacity ranges from a crucible volume of 1200 to 4000 ccm, corresponding to approx. 60 kg of 18 ct. gold.

Power, efficiency, and safety

The TF machines are equipped with 32-bit induction generators providing 15kw - 60kw output power (depending on version). Low-frequency tuning means excellent through-mixing on the molten material. All versions are now controlled via a console with an LCD display with full text readout.

The operational safety of the machines has been optimised in many respects. They are now controlled via an LCD display, with the option of storing 20 temperature presets.

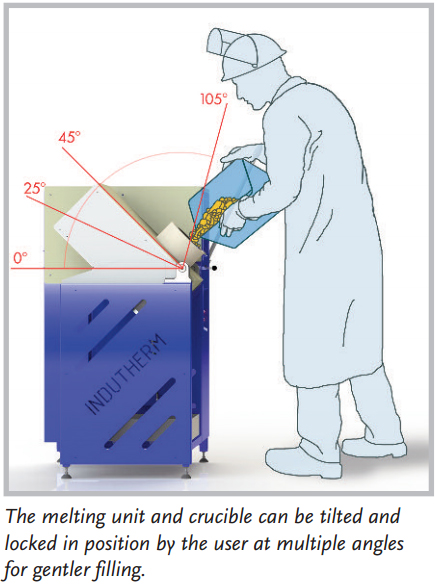

The melting unit and crucible can be tilted and locked in position by the user at multiple angles for gentler filling. Such “soft pouring” also prevents damage to the crucible. Pouring off is continuous and gradual, using a pivot lever. The operator is forced to stand to the side of the machine – away from the dangers of the pouring off area.

In the rare event of a crucible breaking, the machine is not damaged – all of the assemblies are covered by a separate protective housing, and every model has a large collecting tray under the melting unit to prevent potential loss of metal.

Melting uses energy − but ideally as little as possible

We have paid the greatest attention to the energy efficiency and operational safety of the machines. Normally with open melting machines, the induction field that generates the energy for melting the metal is scattered over a relatively wide area. This uses up energy and can be burdensome for the machine operator (electro-smog). As with the large melting machines introduced recently, we have managed to almost completely prevent this scattering of the induction field. The induction energy can then be directed where it is needed – into the crucible or into the molten metals. This technology has enabled tenders to be won against providers with machines that needed double the energy consumption for the same output. The potential for savings is therefore significant, which is a critical criterium for many foundries.

Until recently a high kW figure was the indicator of the performance of a casting machine. Today the majority of customers correctly associate high output with high energy consumption and high costs. The critical thing is to get the maximum benefit from the least possible energy consumption. The new TF machines offer the same maximum outputs as their predecessors – but the effective power consumption for a comparable melting load is significantly lower.

* Due to the size and/or weight of this item, it must be delivered by freight truck. Upon completing your order, a customer service agent will call you to arrange delivery.

TF 1200 |

TF 2000 |

TF 4000 |

|

| Power Max. / Electrical Connection | 15kw (3x400V) | 25kw (3x400V) | 30kw (3x400V) |

| Maximum Temperature | 1500°C | 1500°C | 1500°C |

| Temperature Measurements By Thermocouple | Standard Equipment | Standard Equipment | Standard Equipment |

| Crucible Volume | 1,200ccm = 18kg Au 18ct | 2,000ccm = 30kg Au 18ct | 4,000ccm = 60kg Au 18ct |

| Handling & Control | Tilting By Lever | Tilting By Lever | Tilting By Lever |

| Temperature Control | LCD Display, Full Text Readout | LCD Display, Full Text Readout | LCD Display, Full Text Readout |

| Temperature Programs | 20 | 20 | 20 |

| Interface RS 232 Diagnostic System | Standard Equipment | Standard Equipment | Standard Equipment |

| GSM Modern For Remote Service | Optional | Optional | Optional |

| Dimensions (W x D x H) | 700mm x 600mm x 1250mm | 700mm x 600mm x 1250mm | 700mm x 600mm x 1250mm |

| Weight | 160kg | 160kg | 160kg |

| Packing Qty | Priced individually |

|---|---|

| OEM Parts | Yes |

Log In