How to choose a cutting plier

Deciding which cutters to use among the very large assortment available can be challenging, to say the least. In addition, there can be several good options to choose from for a given application.

We are often asked, ‘Why do you offer such a large range of hand tools, and specifically, so many cutters?’ There are two primary reasons for having such a large assortment. First, the applications served by these tools are almost infinite. From a pure application point of view, more specialized tools are often required to achieve the most cost effective and technically sound result.

In addition, requirements in terms of size and composition of materials to be cut or bent and the end result required can change very rapidly in the fast- moving assembly industry. So maintaining a wide assortment gives you assurance that you can find a good solution for future application requirements that you may not have at present.

This means we have to offer many variations. However, even with that understanding, choosing can still be a challenge! Here are some basic suggestions that can help you narrow your choice to a few very good options.

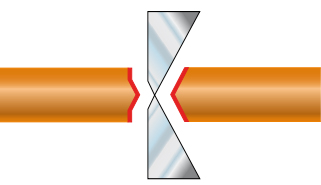

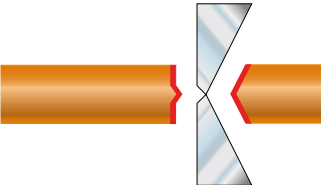

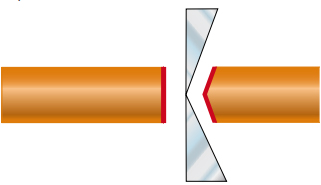

WHAT KIND OF CUTTING RESULT DO YOU WANT?

1.If the cutting result is not critical, then go with the Micro-Bevel as this cutting edge bevel gives you the best capacity and life in most applications.

2.Use the Flush if Micro-Bevel is not suitable

3.Use the Ultra-Flush only when required, as it requires the most care in use.

WHAT ARE THE TYPES AND DIAMETERS OF MATERIAL YOU WANT TO CUT?

All of the Lindstrom brand cutters on our website are rated for copper wire. However, quite often you are not cutting simple copper wire. We rate them for copper as that is a standard that almost all can relate to. Some cutters are also rated for tougher material such as spring wire. However, almost everything else you are cutting will fall in toughness between copper and spring wire.

For instance; is the material a little tougher than copper or a lot? This will further narrow the field by eliminating the cutters not likely suitable for the application.

IS ACCESS (SPACE AVAILABILITY) TO THE APPLICATION AN ISSUE?

If access is not a challenge, then lean towards an Oval head - in as large size as possible - as this is the strongest type of head configuration. One basic fact of the assembly and repair environment is that cutters on a workbench or in the field will at one time or another be used on something either larger or harder than the original intended application. This is when having chosen a Lindström, which is solidly engineered and conservatively rated to begin with and the strongest and largest configuration in the Lindström range that can be used for the application, makes sense. And saves you a lot of money - the tool will much more easily survive occasional misuse and continue to give good results.

If access is an issue, then try to use a smaller Oval head. If that puts you out of cutting range or is still too large at the tip, then move over to a Tapered head. If a Tapered head still doesn’t fit the application, then go with the Tapered and Relieved head.

IS REACH OR ANGLE TO THE APPLICATION AN ISSUE?

Then consider an angle or tip cutter. However, keep in mind that the smallest configurations in this type should then be reserved for that application and used with considerable care.

Comments

Leave A Reply

Your email address will not be published.