The Importance of Clean Equipment

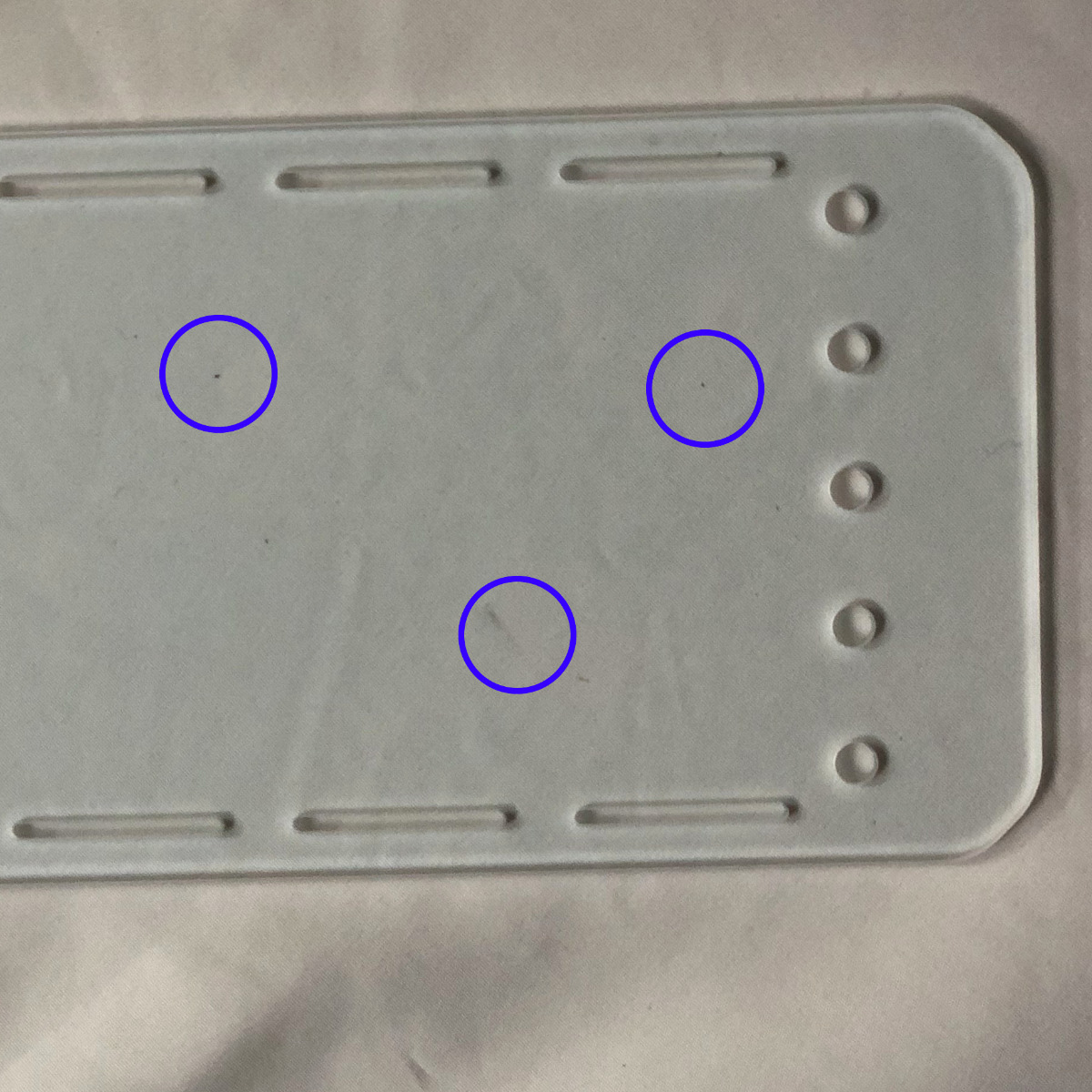

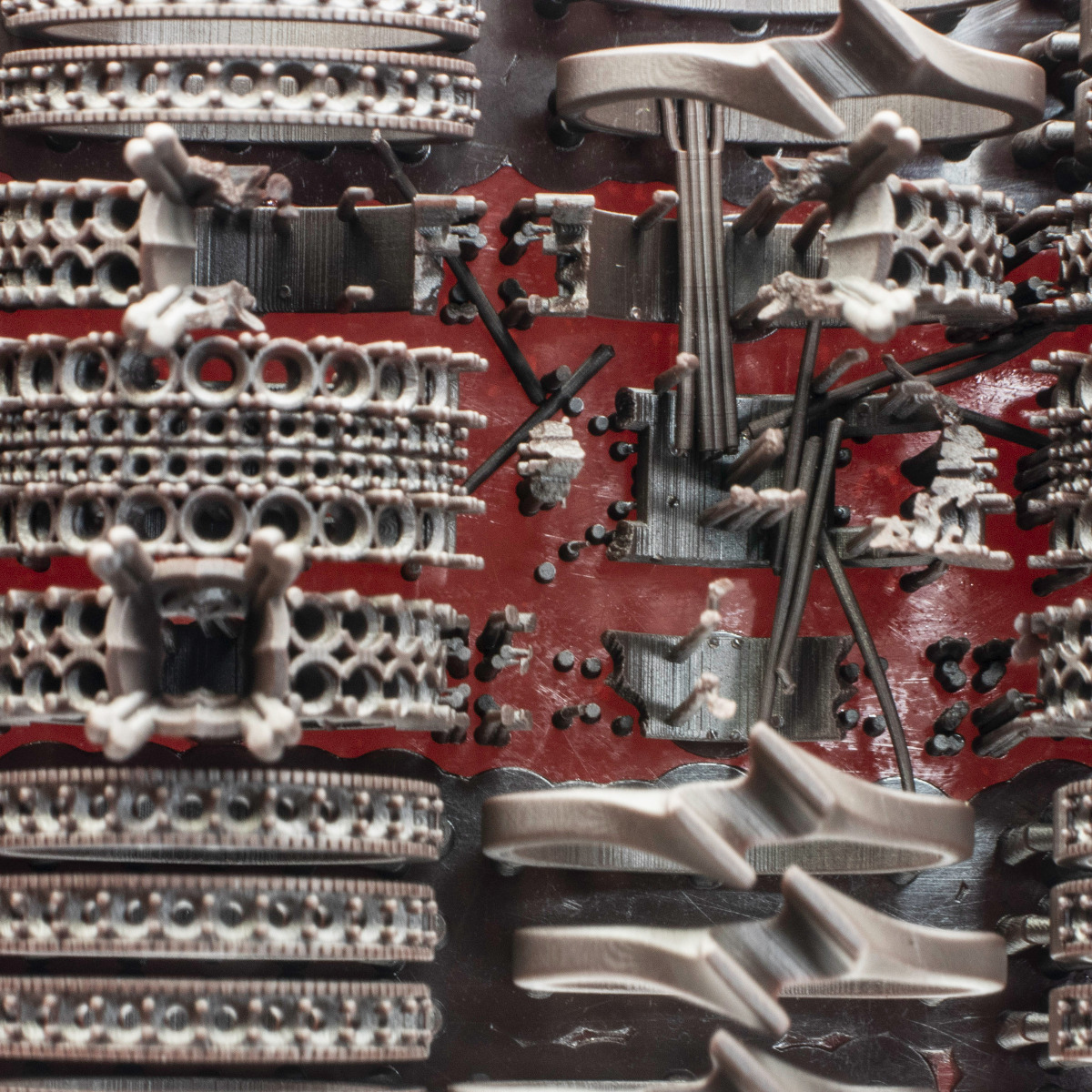

One of the most frustrating parts of 3D printing is a failed print. It can be difficult to determine why a print failed but one of the first steps should always be making sure all of your equipment is as clean as possible. With a digital light processing printer, if there is any contamination on the Teflon tank or the retaining glass, it will disrupt the light and then not build the model. The resin tank and plate must be completely clean to ensure the model will build correctly as even very tiny pieces of debris will cause the build to fail. The first picture shows a failed print and the others are the culprits.

Comments

Leave A Reply

Your email address will not be published.