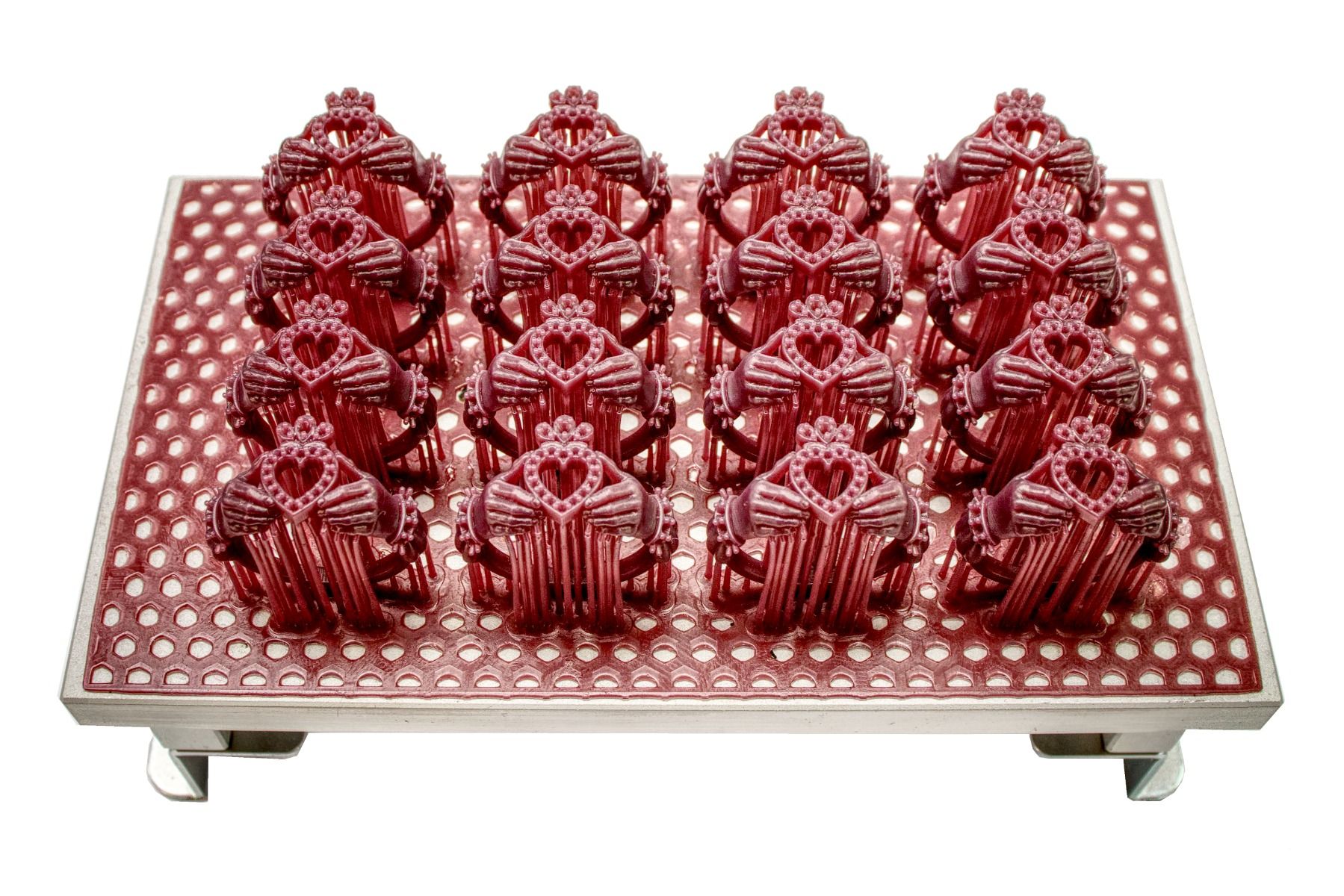

Tiger High Precision 4K 3D Jewelry Printers

Revolutionizing Jewelry Design with High Precision 4K 3D Printers: Introducing the Tiger3D APEX K Series

Revolutionizing Jewelry Design with High Precision 4K 3D Printers: Introducing the Tiger3D APEX K SeriesIn the dynamic world of jewelry design and manufacturing, precision is key. Each intricate detail must be flawlessly captured to bring the designer's vision to life. In this pursuit of perfection, at Romanoff Int, we orrder the Tiger3D APEX K Series. This Resin Jewelry 3D printer emerges as a game-changer, offering unmatched precision, speed, and efficiency in 3D printing technology tailored specifically for the jewelry industry.

Unveiling the Tiger3D APEX K Series

The Tiger3D APEX K Series represents the epitome of innovation in high-definition DLP printers. Boasting cutting-edge features and unparalleled performance, this newest addition to the Tiger3D family is set to revolutionize jewelry manufacturing processes worldwide.Enhanced Speed and Efficiency

One of the most striking features of the Tiger3D APEX K Series is its remarkable speed and efficiency. With a 20% increase in printing speed compared to its predecessors, this advanced 3D printer accelerates production timelines without compromising on quality. Whether crafting intricate filigree designs or elaborate gemstone settings, users can now achieve their desired results in less time, propelling their business forward with unparalleled efficiency.Moreover, the Automatic Cleaning System incorporated into the APEX K Series ensures uninterrupted workflow by keeping the resin tank clear of hardened resin and debris. This automated maintenance feature not only streamlines operations but also preserves the longevity of the printer, minimizing downtime and maximizing productivity.

Furthermore, the APEX K Series distinguishes itself with its open-source system, enabling operators to utilize a wide range of 405um resins. This flexibility not only expands creative possibilities but also enhances compatibility with existing workflows, ensuring seamless integration into established production environments.

Precision Redefined: Protective Layering System

Central to the exceptional precision of the Tiger3D APEX K Series is its innovative Protective Layering System. By meticulously layering each resin deposit, this advanced technology delivers smoother surfaces, sharper details, and superior print quality. As a result, jewelry designers can achieve unparalleled levels of intricacy and refinement, pushing the boundaries of creativity and craftsmanship.In addition to enhancing surface finish, the Protective Layering System reduces the need for support structures, further streamlining the printing process. With fewer supports required, designers can optimize material usage and minimize post-processing efforts, translating into significant time and cost savings.

Unlocking Unlimited Possibilities

Unlocking Unlimited Possibilities

With the Tiger3D APEX K Series, jewelry designers and manufacturers are empowered to expand their creativity and elevate their craft to new heights. Whether producing custom engagement rings, intricate pendants, or exquisite earrings, the unmatched precision and efficiency of this high-definition 3D printer redefine what is possible in jewelry design.As the jewelry industry continues to evolve, embracing cutting-edge technologies like the Tiger3D APEX K Series provides by Romanoff is essential for staying ahead of the curve. With its unrivaled speed, precision, and versatility, this groundbreaking 3D printer is poised to become an indispensable tool for jewelry professionals worldwide, ushering in a new era of innovation and excellence.

Comments

Leave A Reply

Your email address will not be published.