KWS KG100 Auto Flask Unbedding and Flask Cleaning Machine

- Brand: Romanoff

- Max Length of Flask: 280mm

- Max Length of Casting Tree: 280mm

- Dimensions: 850(W) x 650(D) x 1250(H) mm

- Voltage: 400 V / 3-phase / 50 Hz - Optional 220V / 3-phase / 60 Hz

- Weight: 308lbs / 456lbs (gross)

- Country of Origin: United States

- No deformation of the flasks takes place during investment breaking and cleaning

With the development of this Flask Investment Removal Machine, the time to remove investment is greatly reduced by unifying two operations into one system. The automatic removal of the casting tree from the flask and the following removal of the investment from the casting is very efficient. Manual post-cleaning is as good as eliminated! We suggest the Cascade Separator Stainless Steel product # Z50-006-OPT is purchased together with this machine.

Advantages of this system:

- Simple, clean, and automatic operation enabling any unskilled worker to operate this machine

- No deformation of the flasks takes place during investment breaking and cleaning

- Flasks no longer must be cleaned before re-using them

- With an adjustable water jet intensity, no deformation or damage of the castings takes place

- The complete cleaning process takes only 45 to 60 seconds depending upon the size of the tree

- Investment breaking and cleaning of casted trees with preset stones is carried out without any damage

- Stainless steel construction and very heavy-duty components will ensure many years of productivity

| Machine Specs: - Voltage: 400 V / 3-phase / 50 Hz - Also available with optional 220V / 3-phase / 60 Hz - Max Length of casting tree: 280mm - Max length of flask 280mm - Water Consumption: 18 liter per minute - Requires water connection - Dimensions: 850(W) x 650(D) x 1250(H) mm - Net Weight: 308lbs - gross Weight: 456lbs |

|

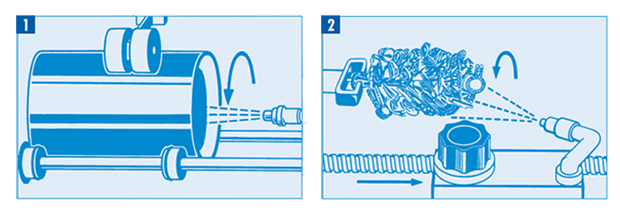

Two operations with one system 1) Unbedding of the casting tree from the flask and removal of the investment compound from the flask with a water jet of 60-95 bars from an adjustable circular jet nozzle. 2) Removal of the investment compound from the casting tree through a water jet coming out of the three movable jets of 95 bars (pressure adjustable). The standard equipment of the machine consists of a circular section jet and two large jet nozzles. Optional a further circular section jet nozzle and a large jet nozzle can be delivered in order to individually adjust the cleaning process to the specific casting tree. |

|

| Packing Qty | Priced individually |

|---|

Log In