KWS EB8 - 5 Flask Flanged Investment Mixing Machine

SKU

76-3002

Link Copied to Clipboard

$22,500.00

- Max Flasks: 5 Flanged Flasks with Maximum Diameter of 140 mm each

- Max Height of Flasks: 230mm / 9"

- Flask Chamber: 380mm Diameter

- Max Powder Capacity: 10kg

- Mixing Chamber Diameter: 280mm

- Height of Mixing Chamber: 315mm (Inside Height)

- Machine Dimensions: 1015 x 550 x 1405mm

- Weight : 147kg / 0025 Pump, 215 kg / 0040 Pump / 226kg / 0025 Pump, 223 kg / 0040 Pump (Crated)

Download Product Brochure

Priced individually

Categories: Investing Equipment, Investment Mixers, KWS

|

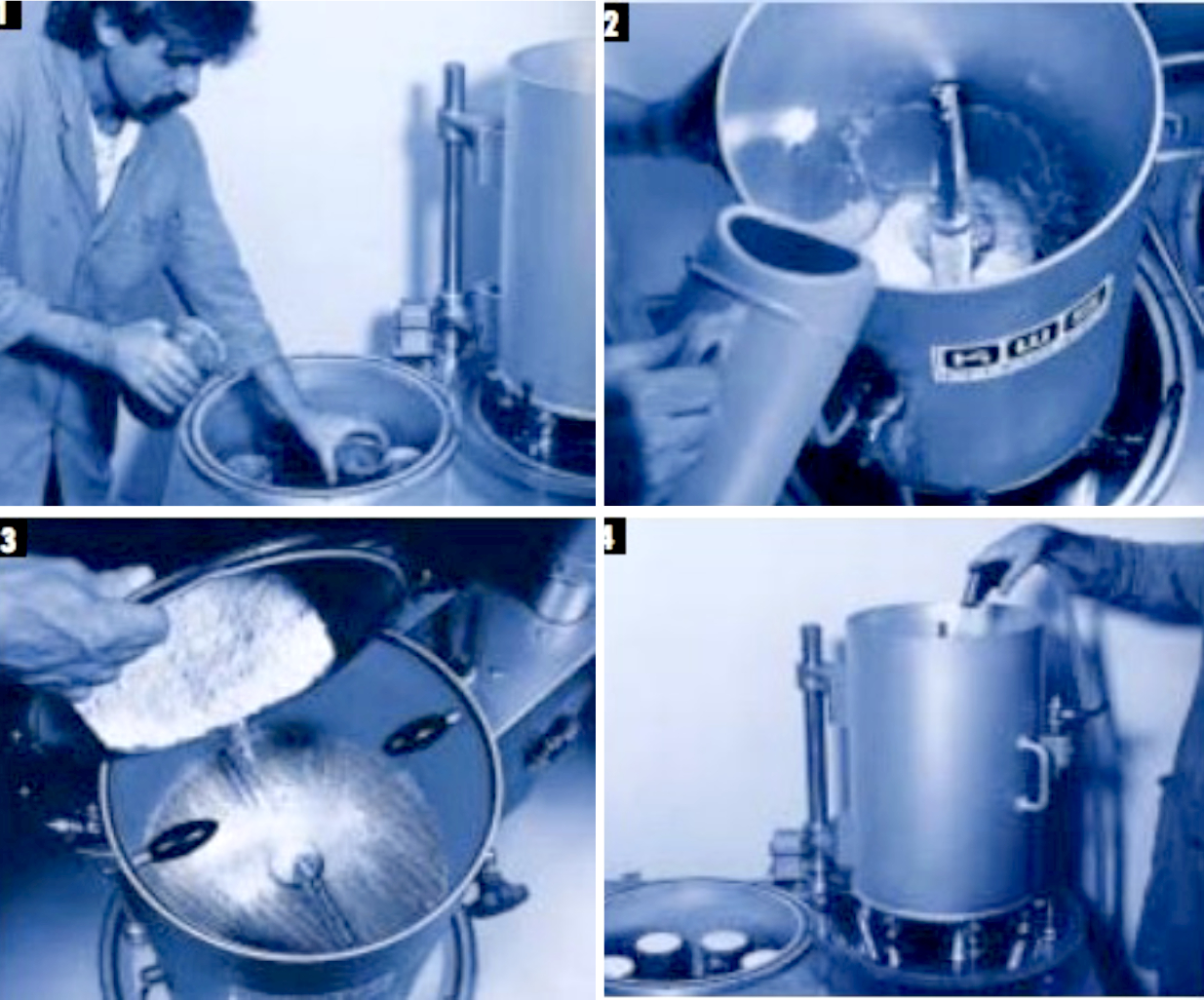

This Romanoff KWS investment mixing machine can mix up to 10 kg of investment powder and is also suitable for smaller output capacity (designer studios). This machine can hold up to 5 flanged flasks at a time. This machine uses standard voltage available in 220/60/3. For flasks of higher height, it is possible to modify the vessel of flasks accordingly. If a higher container is used, the vacuum pump will not be incorporated in the machine.

|

| Technical Details |  |

|

| Form Factor | Floor Unit |

|---|---|

| Application | Investment Mixing |

| Packing Qty | Priced individually |

Log In