KWS EB5 - 3 Flanged Flasks Investment Tabletop Mixing Machine

SKU

76-3001

Link Copied to Clipboard

$13,570.00

- Max Flasks: 3 Flanged Flasks with Maximum Diameter of 120-140 mm

- Max Height of Flasks: 170 mm / 6.8"

- Flask Chamber: 290 mm Diameter

- Max Powder Capacity: 6 Kg

- Mixing Chamber Diameter: 200mm

- Height of Mixing Chamber: 315mm Inside Height

- Power: 220V 3ph 60cyc

- Machine Dimensions: 730 x 490 x 970mm

- Weight: 72 Kg (uncrated) / 120 Kg (crated)

Priced individually

Categories: Casting Equipment, Investing Equipment

Romanoff KWS EB5 Investment Mixing Machines can mix up to 6 kg of investment powder and hold up to 3 Flanged Flasks at a time, suitable for smaller output capacity opperations such as designer studios.

For flasks of higher height, it is possible to modify the vessel of flasks accordingly. If a higher container is used, the vacuum pump will not be incorporated in the machine. This mixer is available for platinum investment compound. This unit uses standard voltage, available in 220/60/3ph.

- High quality casting with a minimum amount of work

The Romanoff KWS EB5 investment machine table top is designed to mix 6 kg of investment compound under vacuum and to simultaneously fill 3 flanged flasks. - High surface quality and contour sharpness on castings

It is now also possible to produce smaller quantities of castings with a high surface quality and contour sharpness. - Pleasant and clean work through simple operation

This mixer is simple to operate and ensures a clean and pleasant working environment. The variable speed mixer guarantees that the correct rotational speed for the specific investment process can be selected at all times. Drive motor and mixing chamber are fixed to each other. This construction avoids malfunction of the machine. - Minimum maintenance needed to maintain the mixer

All parts of the machine are made of stainless steel or of aluminium (Al). This results in minimum maintenance as well as wear and tear. To protect the vacuum pump a filter-system has been installed which improves the life cycle of the pump substantially. The filling taps are made of a special alloy which is not affected by gypsum and water

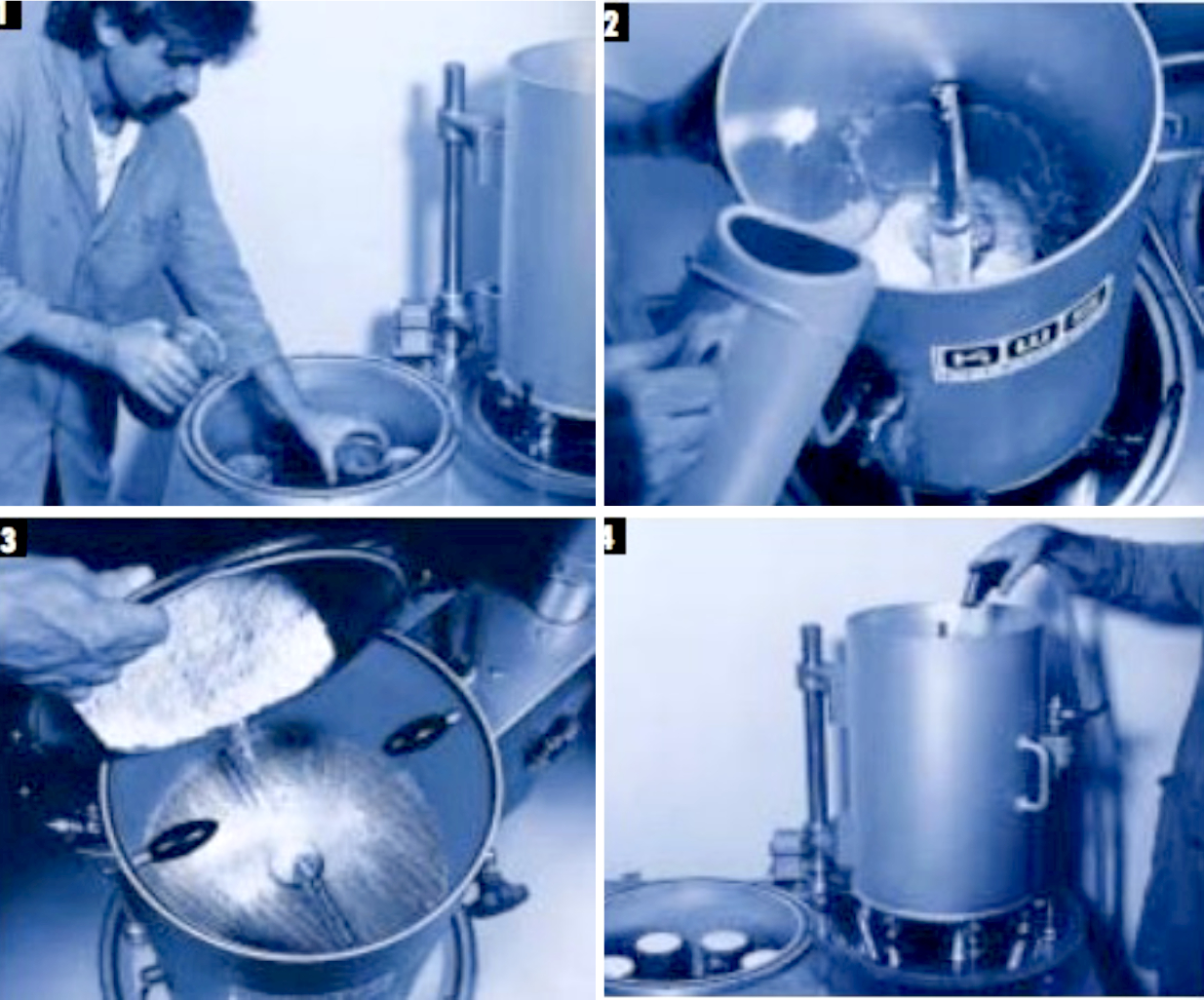

Machine Operation

- 3 flanged flasks are placed in the mixer and the stirring unit is swiveled over them.

- An adequate measured quantity of water is poured into the stirring container.

- The weighed investment material is filled into the stirring container. The mixer is sealed with a plexi-glass lid which allows surveillance of all procedures. Now the investment material is mixed with the water under vacuum. Through the opening of the filling taps the underneath placed flasks are filled while still under vacuum. This procedure and simultaneous vibration allows flasks of highest quality to be produced.

- To clean the machine the mixer is swiveled over the drain bowl and then cleaned with a spray nozzle.

Technical Details

- Filtering system for the protection of the vacuum pump improves the life cycle of the pump substantially.

- The taps are made of a special alloy which is not affected by gypsum and water.

- Gaskets which are affected by the corrosiveness of the gypsum and are used daily, have a life cycle of 2 - 3 years. Through loosening two screws they can be removed for maintenance or replacement (no dismantling).

- Perfect protection against corrosion since all parts are made of aluminium (Al) or stainless steel.

| Form Factor | Tabletop Unit |

|---|---|

| Application | Investment Mixing |

| Packing Qty | Priced individually |

Log In