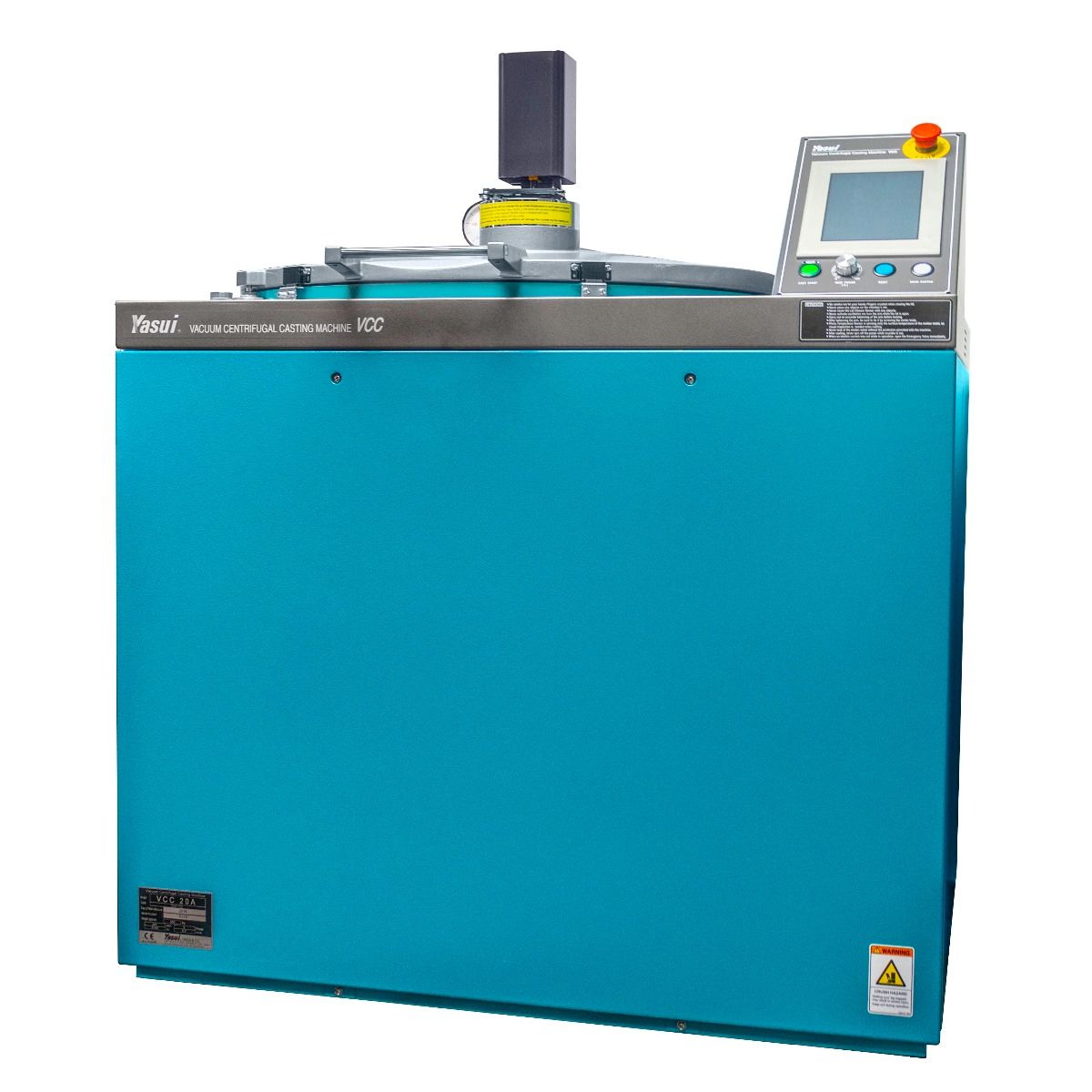

New Yasui VCC Platinum Centrifugal Casting Machine

| Yasui VCC Platinum Centrifugal Casting Machine | |

|---|---|

| Brand: | Yasui |

| Model: | VCC Platinum Centrifugal Casting Machine |

| Power: | AC200V, 50/60 Hz, 3 Phase, 6.5kVA |

| Temp. Control Range: | 900°C ~ 2100°C |

| Flask Size: | DIA. 76 mm / 80 mm |

| Maximum Length: | 100mm |

| Platinum Crucible Capacity: | 400 g (51mm dia.) |

| Features | Double Swing Broken Arm |

| Dimensions(in) | 41" x 32" x 47" |

| Net Machine Weight | 350kg |

The best and most reliable Platinum Casting Machine produced today!

The Yasui VCC features the exclusive "Double Swing Arm" patented technology to ensure zero turbulence, complete filling, and dense castings every time! An accurate temperature is achieved by the dual spectrum optical thermal control system guaranteeing consistent and casting temperatures ±2°C. The unit features a completely vacuumed casting chamber that removes all unwanted gases and backfills with inert argon gas. The acceleration rate and the RPM of the casting arm can be programmed independently and can reach top RPM speed in less than one-third of a second. The cooling system has a built-in water circulation system with a temperature controller to protect the heating coil in case of power failure.

Features:

- Full auto mode, semi-auto mode, and manual mode are available.

- Stepless control of rotational speed and initial spin-up.

- Built-in High-performance Servo-Motor

- Double Swing Arm

- Digital touch panel control

Setting:

- Setting change that was not possible by the conventional machine is now possible on the touch panel.

- Even better quality castings can be achieved.

Alarm:

- The alarm indicators are displayed separately from the error indicators.

Double Swing Arm

By the originally developed Yasui "Double Swing Arm" (Japan Patent No. 3178748), the molten metal can be poured into the mold straight without loss. Improvement of filling efficiency, metal density, and substantial reduction of metal loss has been realized.

Frequently asked questions

Q: What is the benefit of the Double Swing Arm?"

A: The Double Swing Arm allows the molten metal to be transferred directly into the mold within the machine, greatly improving efficiency and metal density while substantially reducing metal loss

Q: Does this machine require a vacuum pump?

A: Yes, the Yasui VCC Platinum Casting Machine does require a vacuum pump. We recommend the following: SKU: 004-220-R

Manual Mode:

- The operator can determine casting timing freely in the case of manual mode.

- Different from the conventional machine, various settings can be performed on the touch panel.

- Further, the initial spin-up speed of rotation has been improved.

Automatic Mode:

- In automatic mode, automatic gas and vacuum wash cycles can be used during the melting process.

- Different from the conventional machine, the semi-auto mode is available, and also the full-auto mode can operate automatically to the finish of the casting (rotation).

Stepless control of rotation speed and initial spin-up speed - new type high performance servo-motor:

- Initial spin-up time required to achieve final rotation speed can be set freely (the fastest initial spin-up speed is 500RPM by 0.1sec.

- Initial spin-up speed of this machine is 500RPM by 0.1sec. (The previous model VCC was 500RPM by 0.2sec.) By this, the machine can process more metals.

- Descending time of the coil is greatly shortened to 40msec. (The previous model VCC was 200msec.) Increased production is possible.

Thermal Control with High Accuracy

- Thermal control with high accuracy is possible by the optical thermal controller.

- In addition to heating control by the temperature controller, the machine is newly equipped with the heat power control dial, so upper limit output can be adjusted steplessly

*Vacuum pump not included.

|

|

|---|---|

| Specification | Yasui VCC Platinum Centrifugal Casting Machine |

| Oscillation Power | 5kW |

| Oscillation Frequency | Approx. 100kHz |

| Temp. Control Range | 900~2100°C |

| Temp. Control Method | PID Control |

| Melting Capacity | 400G Pt |

| Flask Size | DIA. 76mm / 80mm Max. length 100mm |

| Max Acceleration | 500 RPM - 0.1 sec |

| Dimensions (WxDxH) | 1020mm x 790mm x 1180mm |

| Net Weight | Approx. 350kG |

| Power Supply | AC200V, 50/60 Hz, 3 Phase, 6.5kVA |

| Metal Type | Platinum, Stainless Steel |

|---|---|

| Form Factor | Floor Unit |

| Packing Qty | Priced individually |

Log In